Machining

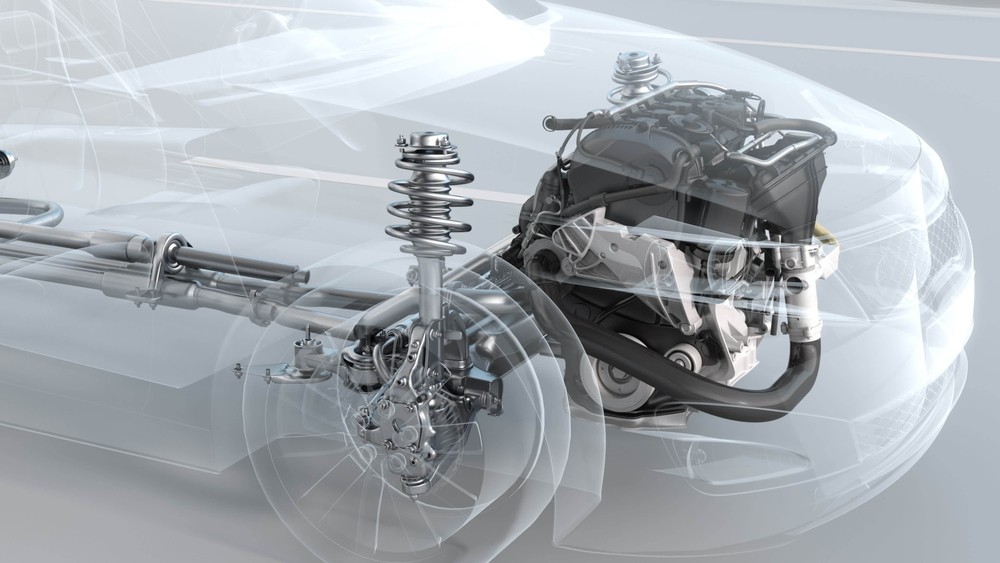

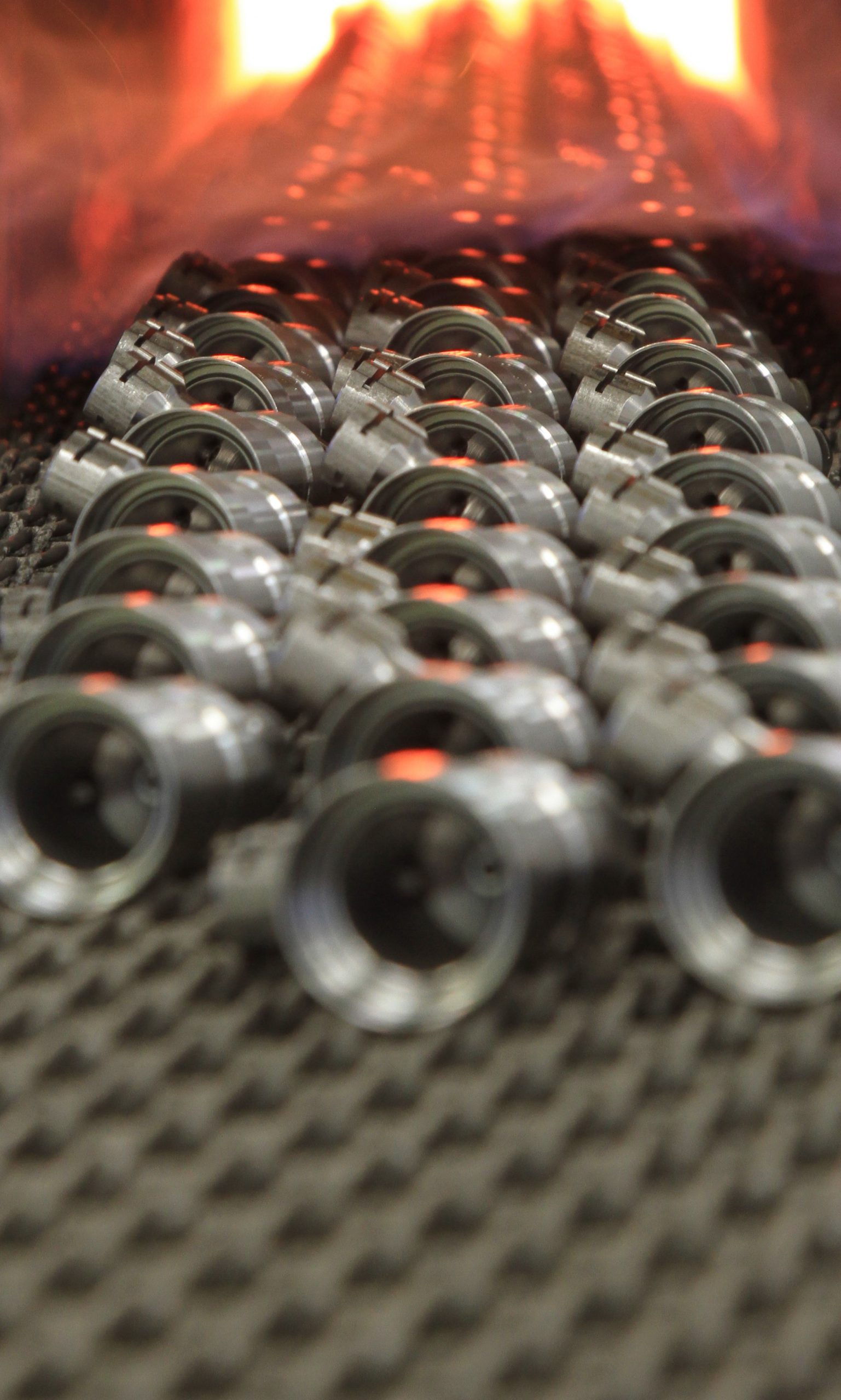

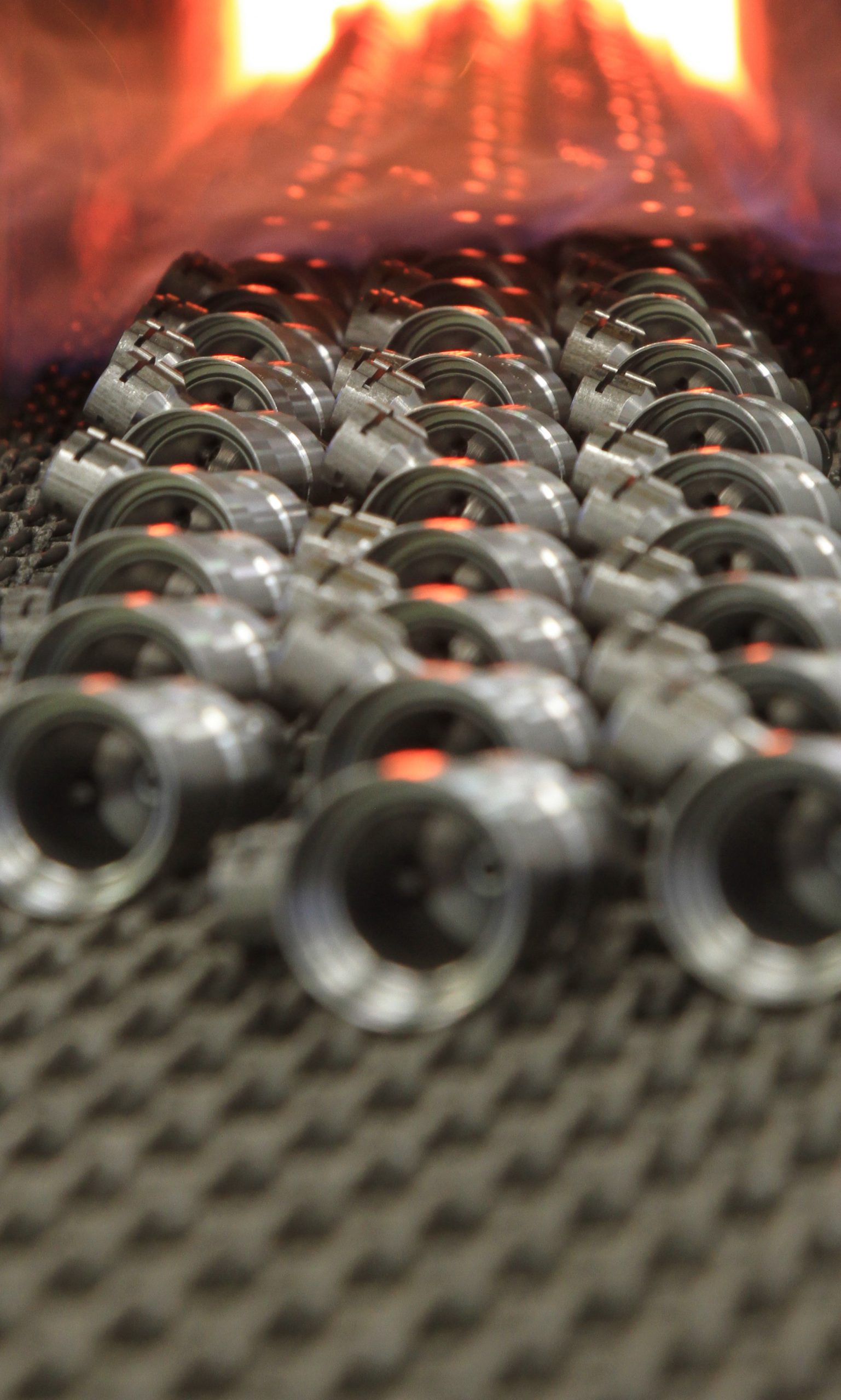

In our machining lines, all of which consist of CNC turning and CNC machining centers, metals such as steel, casting, aluminum and bronze are obtained in cast, forged or cold drawn forms, and then the desired size is achieved by turning, milling, drilling, grinding and honing processes in precise tolerances....

Continue TR

TR  FR

FR