Talaşlı Üretim

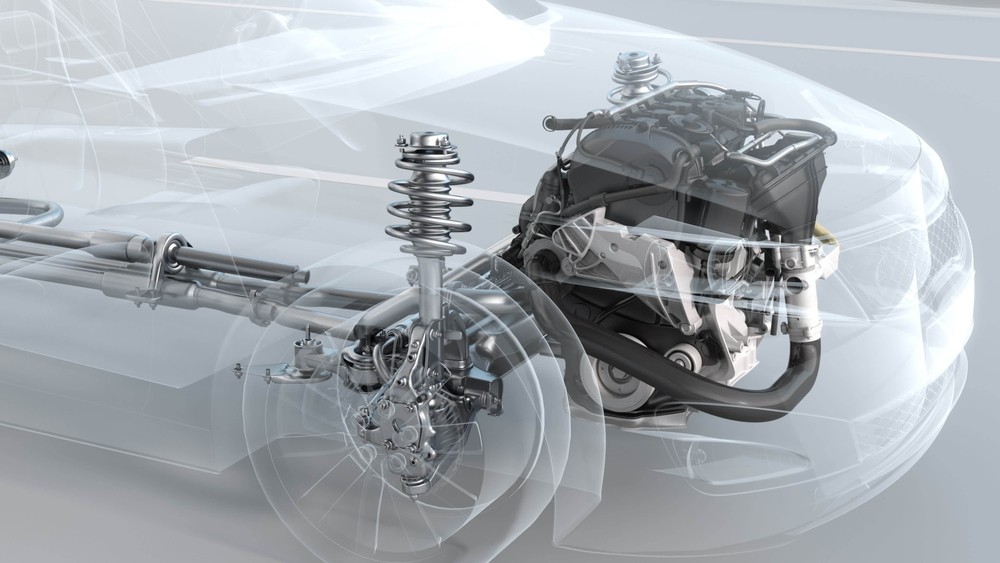

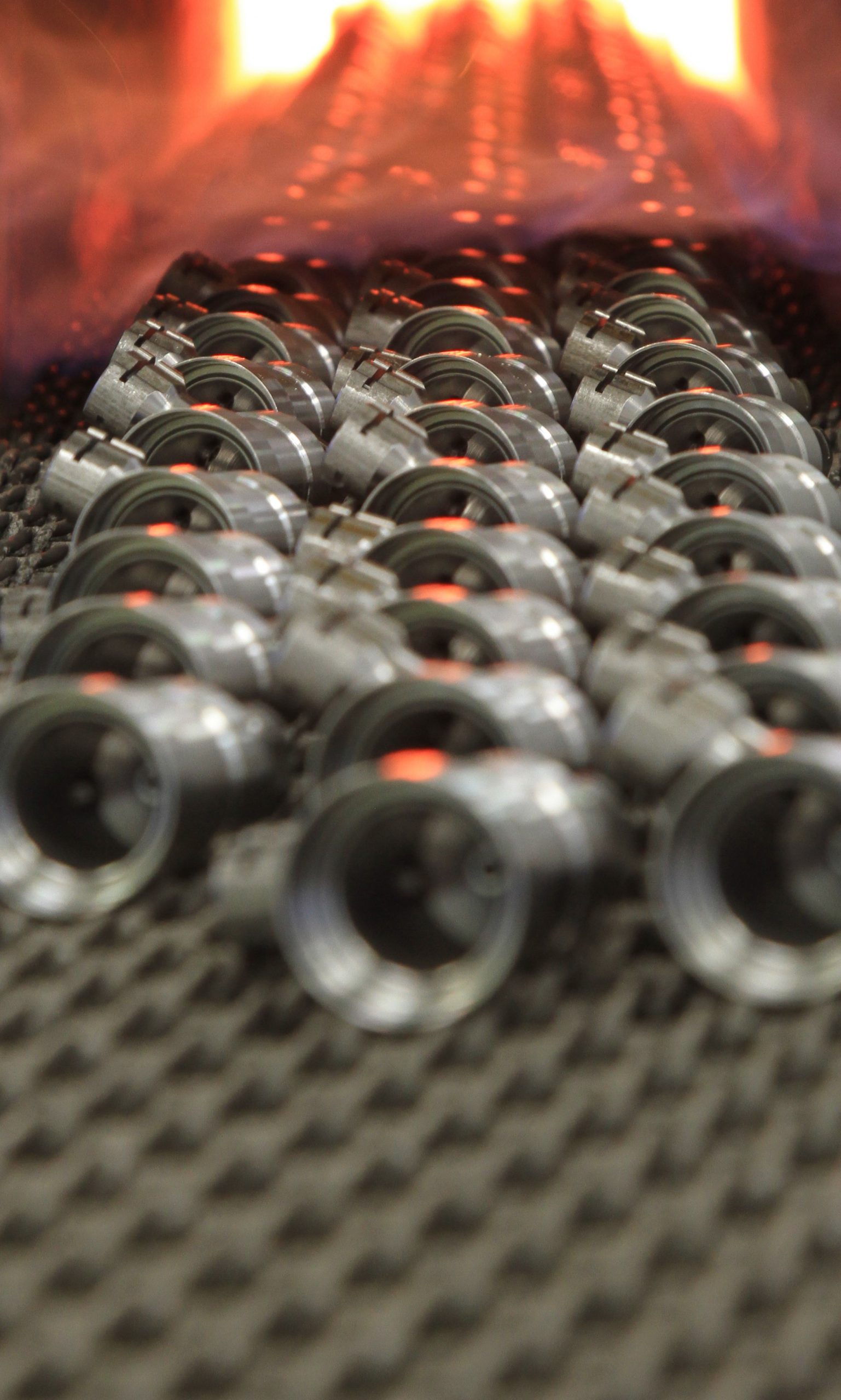

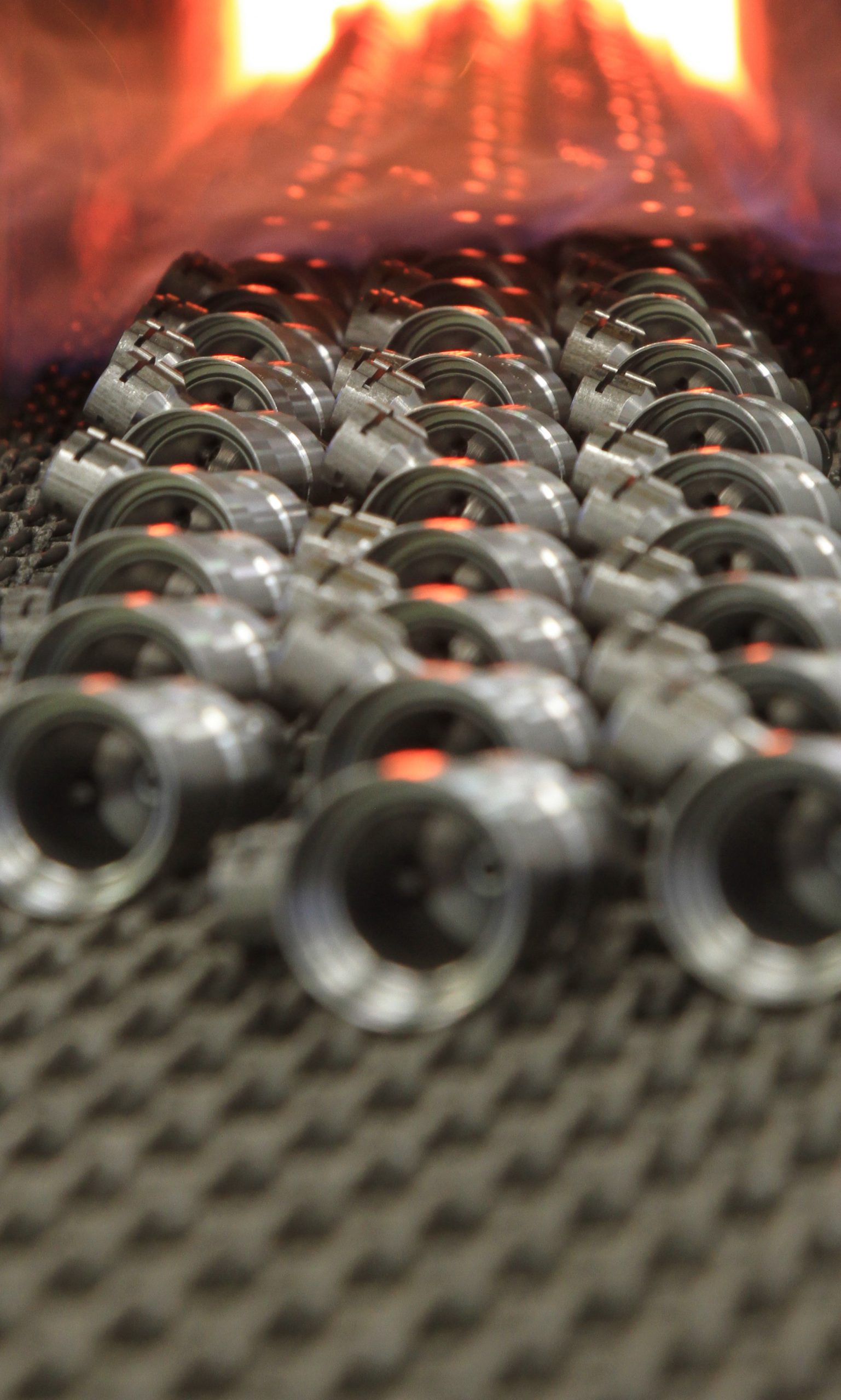

İşleme hatlarımızda CNC torna ve CNC işleme merkezleri kullanılarak, çelik, döküm, alüminyum ve bronz gibi metaller işlenmektedir. Dökme, dövme veya soğuk çekilmiş olarak temin edilen hammaddeler, hassas toleranslarda tornalama, frezeleme, delme, taşlama ve honlama işlemleri ile istenen ölçü ve yüzey kalitesine getirilir. Üretim sürecinde yüksek hassasiyetli ölçüm ekipmanları ve kalite kontrol prosedürleri uygulanarak müşteri taleplerine uygun ürünler sunulmaktadır.

Devam EN

EN  FR

FR